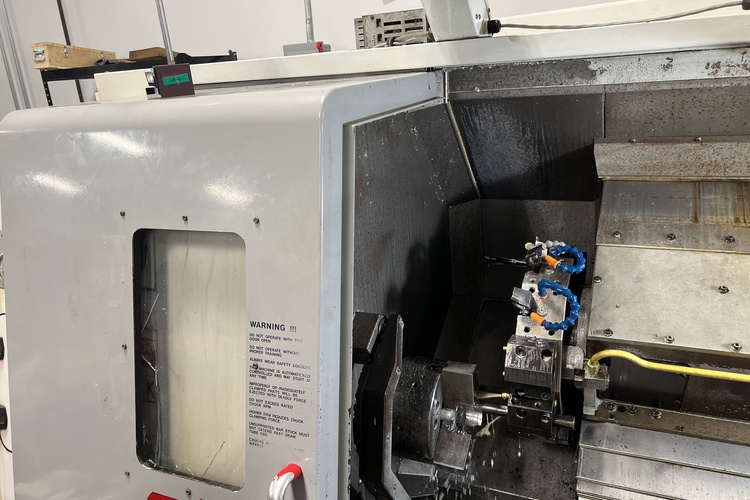

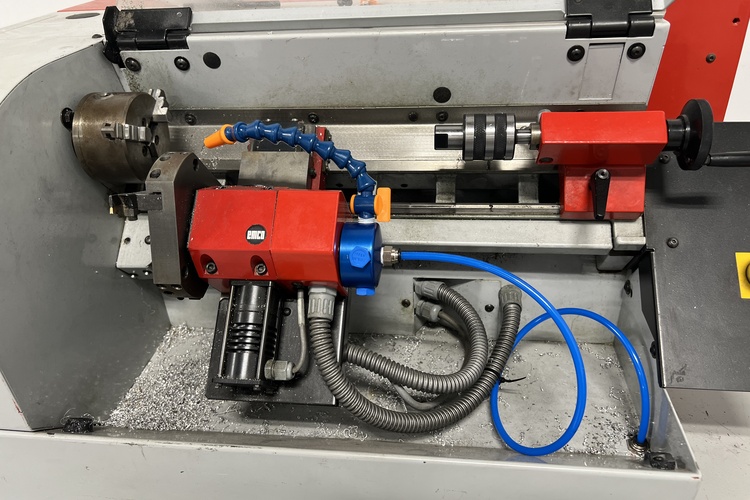

CNC Lathe + CAM

Use of the CNC Lathe is critical for producing higher tolerance and more complex machined parts. Students who have completed the manual lathe class will learn basic CAM skills using Fusion 360 such as CNC feed and speed calculations and tool path selection along with basic control operation.

This is a 4 day class, you must attend all 4 sessions.

-Day 1- CAM basics, Machine Control Basics, Basic Facing and OD Turning (4 hrs)

-Day 2- Drilling and Boring (4 hrs)

Day 3- OD Grooving, ID Grooving, Parting (4 hrs)

Day 4- Threading and Review (4 hrs)

AGE REQUIREMENT: 18+

Students will perform individual small projects inline with the templates provided by the instructor.

Prerequisites: Fusion360 CAD, Manual Mill

Completion of this workshop serves as a checkout for utilizing the CNC mills in the machine shop.

* Fee Notes: All materials included

Requirements: Closed toed shoes, natural fibers with no loose clothing

Prerequisites: Fusion 360 CAD, Basic Machine Shop Technology - Lathe

Email me the next time this class is scheduled